Станок для резки кварца

SH60-R — это высокоточный горизонтальный станок с бесконечной алмазной проволокой, предназначенный для резки кварцевых блоков, технической керамики и других твёрдых, хрупких материалов. Оснащённая полностью программируемой системой перемещения по осям YZ и вращающимся загрузочным столом, модель SH60-R обеспечивает стабильную резку без сколов, идеально подходящую для высокочистых оптических, полупроводниковых и научных стеклянных изделий.

Ключевые особенности

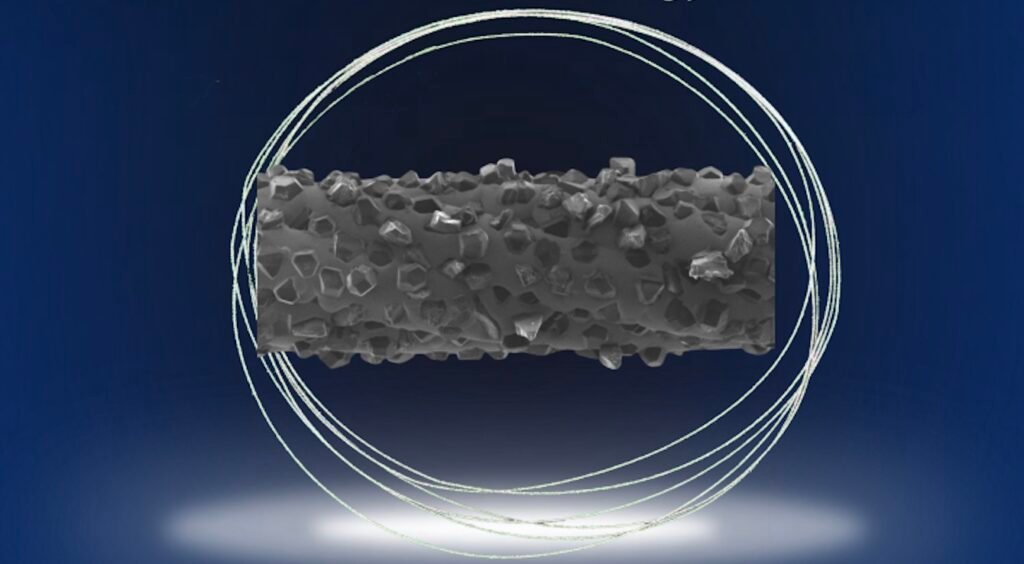

Резка бесконечной алмазной проволокой

Использует гальванически покрытую высокоскоростную алмазную проволочную петлю для резки любых материалов, мягче алмаза — включая кварц, оптическое стекло, кремний и керамику.

Полностью программируемая резка

Задайте желаемую толщину среза и скорость резки — станок выполнит процесс автоматически с точностью подачи ±0,01 мм.

Перемещение по осям YZ + вращающаяся платформа

Линейная система перемещения по двум осям (YZ), управляемая сервоприводами, с рабочим столом, вращающимся на 360° для стабильного контакта с режущей поверхностью.

Сенсорный интерфейс управления

Оснащён удобной ПЛК-системой с сенсорным экраном и ручным контроллером на английском языке для простого управления.

Интегрированная система водяного охлаждения и циркуляции

Встроенный водяной бак и система рециркуляции обеспечивают чистую и низкотемпературную работу при обработке чувствительных оптических материалов.

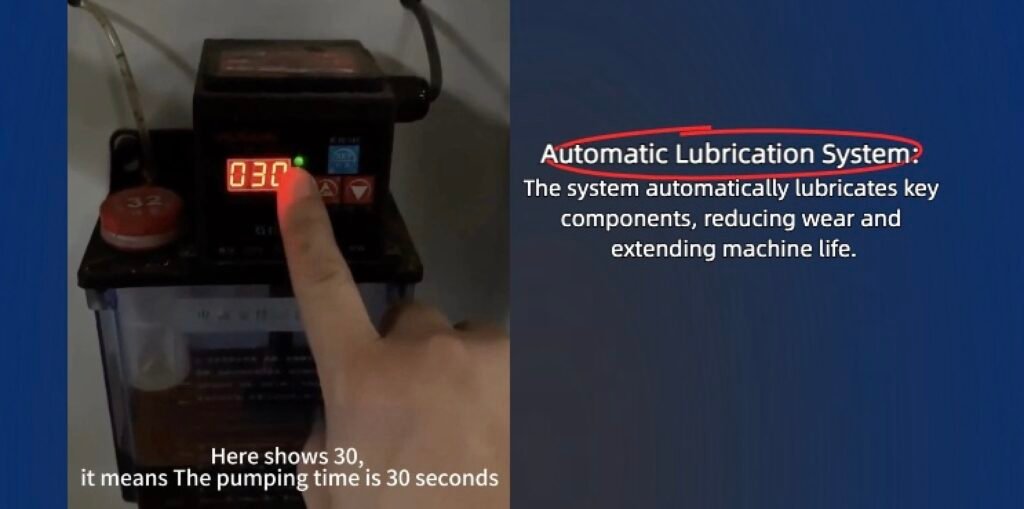

Автоматическая система смазки

Ключевые подвижные части автоматически смазываются, что снижает износ и продлевает срок службы оборудования при минимальном ручном обслуживании.

Система улавливания масляного тумана

Закрытая камера резки со встроенной системой сбора масляного тумана обеспечивает более чистую и безопасную рабочую среду при высокоскоростной резке.

Технические характеристики SH60-R

Параметр | Значение |

|---|---|

Диаметр рабочего стола | Ø600 мм |

Макс. высота заготовки | 500 мм |

Ход по оси Y | 315 мм |

Ход по оси Z | 500 мм |

Длина алмазной проволоки | ~3500 мм |

Диапазон диаметра проволоки | 0,35 – 1,0 мм |

Макс. скорость проволоки | 84 м/с |

Мин. шаг подачи (Y/Z) | 0,01 мм |

Повторяемость (Y/Z) | ±0,01 мм |

Диапазон скорости резки | 0–1000 мм/мин (регулируется) |

Размер направляющих роликов | Ø250 мм / Ø180 мм |

Мощность двигателя | 0,75 кВт (макс. 2800 об/мин) |

Электропитание | 220В, 50Гц, 3 фазы |

Размеры станка (Д×Ш×В) | 1646 × 1733 × 2010 мм |

Собственный вес | ~1300 кг |

Резка нестандартных форм | Не поддерживается |

Видео резки от клиентов: реальная производительность

Сравнительная таблица: станки для резки крупных кварцевых блоков

Метод резки | Точность | Качество поверхности | Ширина пропила | Скорость | Подходящий размер | Потери материала | Типичное применение |

|---|---|---|---|---|---|---|---|

Бесконечная алмазная проволока | Очень высокая | Очень высокое | 0,6–0,9 мм | Очень низкая | Очень крупные | Низкие | Прецизионная резка кварца, керамики, стекла |

Многопроволочная пила | Средняя | Средне-высокое | 0,1–0,3 мм | Низкая | Средние – крупные | Низкие | Массовая резка пластин (ограниченная гибкость по форме) |

Алмазная ленточная пила | Средняя | Среднее | >1,0 мм | Высокая | Очень крупные | Высокие | Грубая предварительная нарезка, сегментирование |

Гидроабразивная резка | Средняя | Среднее | ~1,0–2,0 мм | Средне–высокая | Крупные | Средние | Резка по форме толстых блоков с низким термическим воздействием |

Лазерная резка | Зависит от типа | Высокое | Малые – средние | Средне–высокая | — | — | Не подходит для кварца из-за плохого поглощения ИК-излучения |

Пила с внутренним диаметром (ID) | Низкая | Низкое | ~0,3 мм | Низкая | Малые (≤300 мм) | Низкие | Нарезка тонких пластин из кварцевых прутков или дисков |

Как это работает: устройство SH60-R изнутри

Типичные области применения этого станка для резки графитовых лодочек

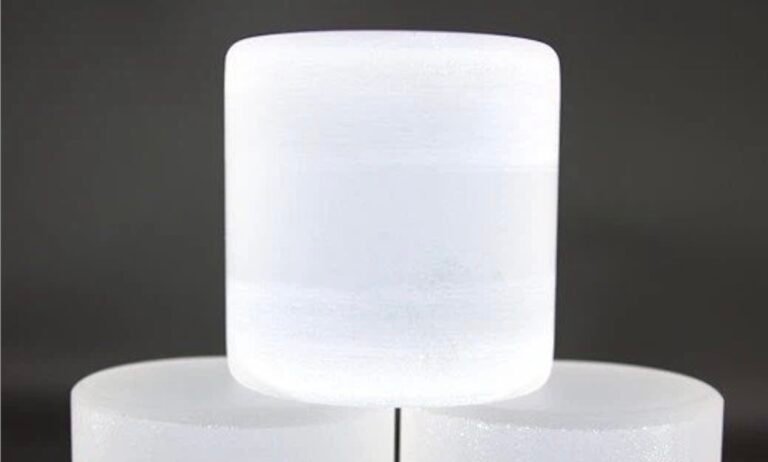

Резка кварцевых блоков

Для оптических подложек, инфракрасных окон и высокочистых фотонных компонентов.

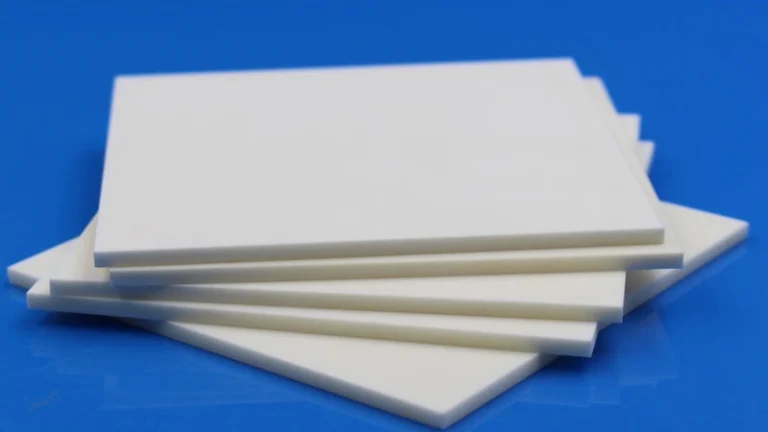

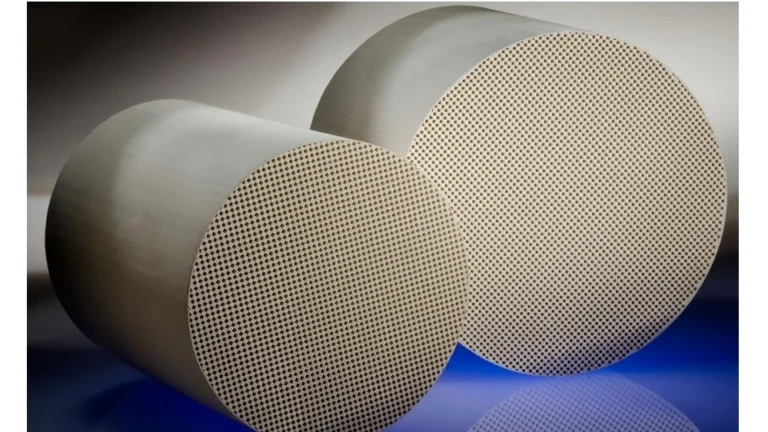

Ceramic Material Processing

Suitable for Al₂O₃, AlN, Si₃N₄, and other engineering ceramics used in electronics and optics.

Резка оптических стеклянных пластин

Для чистовой резки оптических компонентов, таких как подложки фильтров или лазерные окна.

Предварительная обработка полупроводниковых материалов

Для резки кремниевых слитков или других хрупких материалов высокой стоимости.

Почему выбирают нас

Высокоскоростная резка бесконечной проволокой

Высокожесткая литая конструкция

Высокоточные направляющие и шарико-винтовая передача

Автоматическая система постоянного натяжения

Микронный контроль подачи

Удобный интеллектуальный интерфейс

Полностью закрытая защитная конструкция (опционально)

Низкие эксплуатационные расходы и высокая экономичность

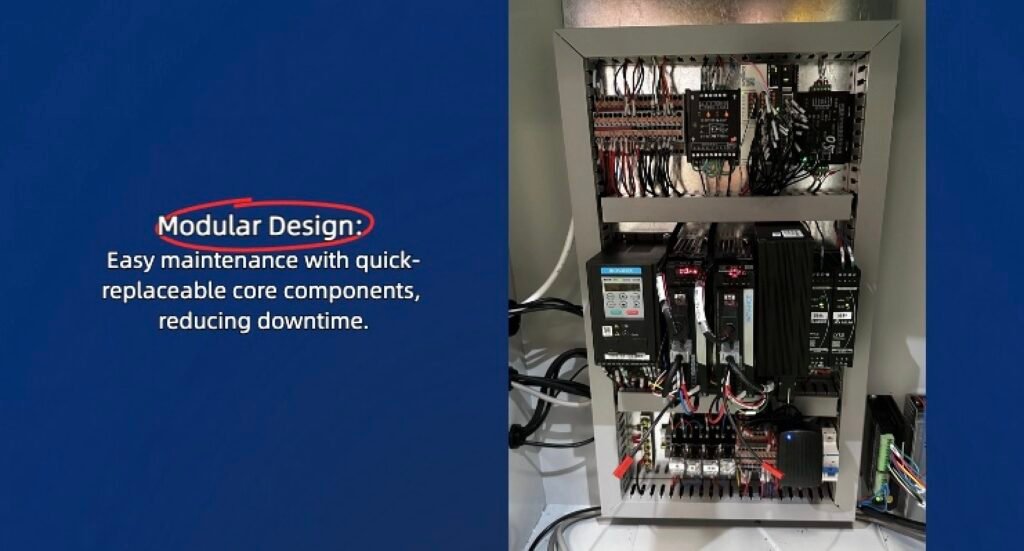

Модульная конструкция

Низкие затраты на обслуживание и высокая рентабельность

Автоматическая система смазки

Отзывы клиентов

Часто задаваемые вопросы

Какова максимальная толщина материала, которую может обрабатывать станок при резке?

Станок способен резать заготовки толщиной от 0,1 до 100 мм и может выполнять автоматическую резку после настройки программы.

В чём разница между этой проволочной пилой и ленточной пилой?

Скорость резки будет примерно одинаковой, но качество поверхности после резки проволочной пилой значительно лучше, а потери материала (ширина пропила) — меньше.

Как станок сводит к минимуму потери материала при резке?

Модель HorizonCrystal оснащена высокоточной алмазной проволокой диаметром от 0,35 до 0,8 мм, благодаря чему ширина пропила остаётся минимальной.

Каков ожидаемый срок службы алмазной проволоки, и можно ли заменить её самостоятельно?

Требуются ли для работы станка специальные условия или специализированная среда?

Какую техническую поддержку и гарантию вы предоставляете при покупке этого оборудования?

Мы предоставляем комплексную гарантию сроком на 1 год, а также видеоподдержку или выездное техническое обслуживание после покупки, чтобы обеспечить максимальную эффективность работы вашего оборудования и оперативное решение любых возникающих проблем.