Стеклорез с колебательной проволокой

Модель SGSM 40 — это вертикальный станок с бесконечной алмазной проволокой, предназначенный для эффективной резки средних и крупных твёрдых и хрупких материалов, таких как сапфир, алюмина, кварц и керамика. Его ключевая особенность — это высокоскоростное вертикальное движение резки в сочетании с программируемыми колебаниями проволоки вверх и вниз, что обеспечивает двойной эффект «резка + полировка», позволяя получать более гладкие поверхности и увеличивать производительность.

ОСНОВНЫЕ ОСОБЕННОСТИ

Резка с колебательной проволокой для гладкой поверхности

Движение проволоки по оси Z включает программируемые колебания вверх и вниз во время резки. Такое качающееся движение имитирует эффект полировки поверхности, значительно улучшая её качество и снижая вероятность сколов по краям.

Оптимизировано для средних и крупных твёрдых материалов

Поддерживает заготовки размером до 400 × 400 × 400 мм, что делает станок идеальным для резки крупной керамики, сапфировых подложек, кварцевых блоков и других подобных материалов.

Полностью закрытый корпус с портальной конструкцией

Вертикальная портальная рама обеспечивает механическую стабильность и точность резки, а полностью закрытый корпус повышает безопасность и эффективность пылеудаления при высокоскоростной резке.

Сенсорный экран + ручной пульт управления

Оснащён двухъязычной PLC-системой (китайский/английский). Оператор может задавать параметры, такие как амплитуда колебаний, скорость проволоки и скорость подачи, с помощью интуитивно понятного сенсорного экрана и ручного пульта.

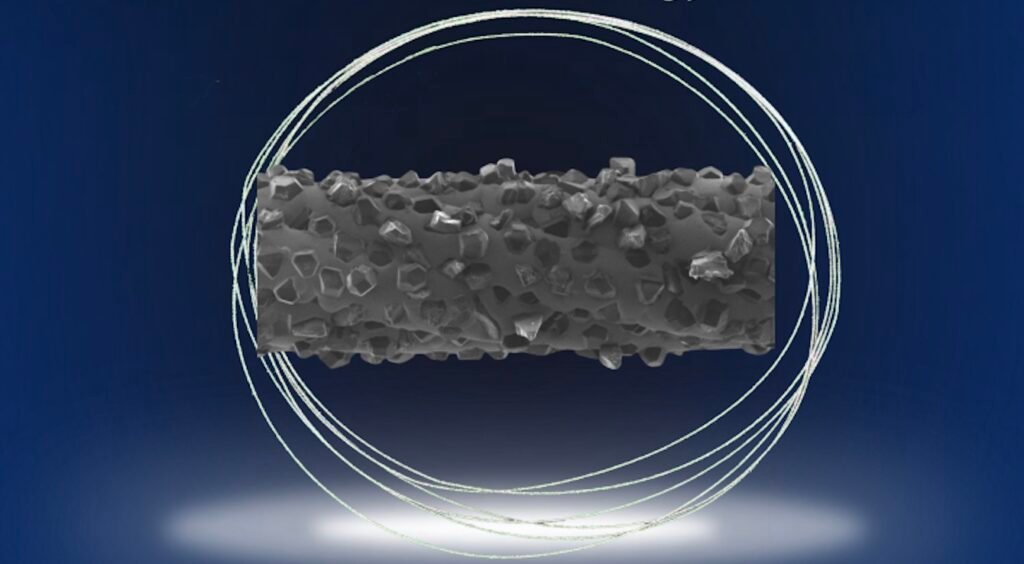

Высокоскоростная система бесконечной проволоки

Используется электроосаждённая алмазная проволока диаметром Ø0,35–1,0 мм с максимальной линейной скоростью 38 м/с. Привод осуществляется двигателем на 2100 об/мин для быстрой и стабильной резки.

Привод подачи по двум осям с сервомоторами

Оси Y и Z используют шарико-винтовые пары и направляющие, приводимые в движение сервомоторами. Разрешение подачи составляет 0,01 мм, а повторяемость — ±0,02 мм.

Интегрированное охлаждение и смазка

Включает автоматическую масляную смазку подвижных компонентов и систему водообращения для охлаждения зоны резки, что позволяет сохранять чистоту поверхности и продлевает срок службы проволоки.

Технические характеристики SGSM 40

№ | Наименование | Технические характеристики |

|---|---|---|

1 | Макс. длина заготовки (мм) | 400 |

2 | Макс. ширина заготовки (мм) | 420 |

3 | Макс. высота заготовки (мм) | 350 |

4 | Ход рабочей оси Y (мм) | 400 |

5 | Ход рабочей оси Z (мм) | 350 |

6 | Макс. скорость алмазной проволоки (м/с) | 33 |

7 | Мин. шаг подачи по оси Y (мм) | 0,01 |

8 | Мин. шаг подачи по оси Z (мм) | 0,01 |

9 | Точность повторного позиционирования оси Y (мм) | 0,01 |

10 | Точность повторного позиционирования оси Z (мм) | 0,01 |

11 | Общая потребляемая мощность (кВт) | 3,5 |

12 | Электропитание | 220В, 50Гц |

13 | Габариты станка (мм) | 1350 × 1050 × 1850 |

14 | Масса станка (кг) | 3500 |

15 | Давление воздуха (МПа) | 0,5–0,8 |

Демонстрация резки

Для того же метода резки с колебаниями мы также предлагаем модель SGR40, в которой используется колебание заготовки вместо колебания проволоки.

Сравнение качества поверхности после резки

СРАВНЕНИЕ МЕТОДОВ РЕЗКИ

Фиксированная, колебательная и вращательная резка: выбор подходящего движения для твёрдых материалов

Бесконечная алмазная проволочная резка предлагает несколько стратегий движения, каждая из которых оптимизирована для разных уровней твёрдости, скорости и требований к качеству поверхности. Ниже представлено сравнение трёх основных методов:

Метод | Описание | Скорость резки | Качество поверхности | Сложность управления | Наилучшее применение |

|---|---|---|---|---|---|

Фиксированная резка (например, SG 40) | Проволока и заготовка остаются неподвижными в направлении; только прямолинейная резка | ⭐⭐ | ⭐⭐ | ⭐ Очень простая | Среднетвёрдые материалы |

Колебательная резка (например, SGSM 40) | Проволока или заготовка совершают движения вверх-вниз во время резки | ⭐⭐⭐ | ⭐⭐⭐⭐ Отличное | ⭐⭐ Простая | Ультратвёрдые хрупкие материалы |

Вращательная резка (например, SH40-R) | Заготовка непрерывно вращается (обычно на 360°) во время резки | ⭐⭐⭐⭐ Самая быстрая | ⭐⭐⭐ Хорошее | ⭐⭐⭐ Более сложная | Ультратвёрдые компоненты |

Типичные области применения

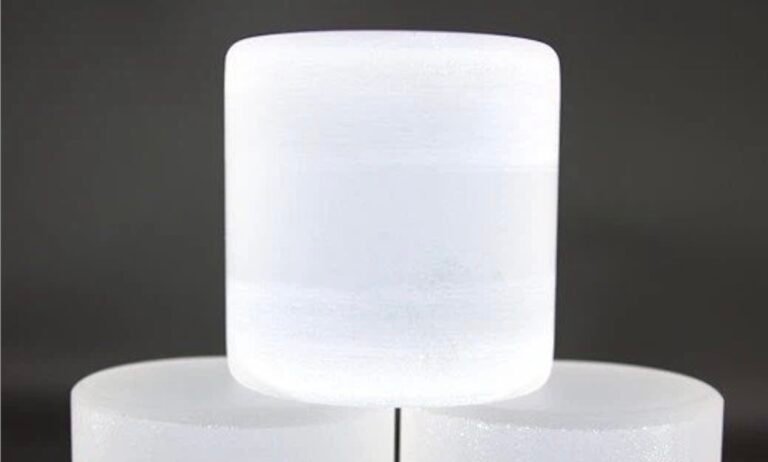

Резка сапфировых пластин

Используется для распила сапфировых слитков или блоков на пластины для подложек светодиодов, окон часов, оптических куполов и компонентов датчиков. Система с качающейся проволокой снижает количество сколов по краям и устраняет необходимость в последующей полировке, что особенно важно при выращивании кристаллов.

Резка подложек из карбида кремния (SiC)

Supports clean slicing of SiC blocks or thick wafers used in high-voltage power electronics and EV semiconductors. Enables better wafer yield with low material loss.

Fused Quartz & Fused Silica

Точная резка высокочистого кварца для оптики, преформ оптоволокна и ИК-окон. Резка без вибраций сохраняет прозрачность и стабильность размеров.

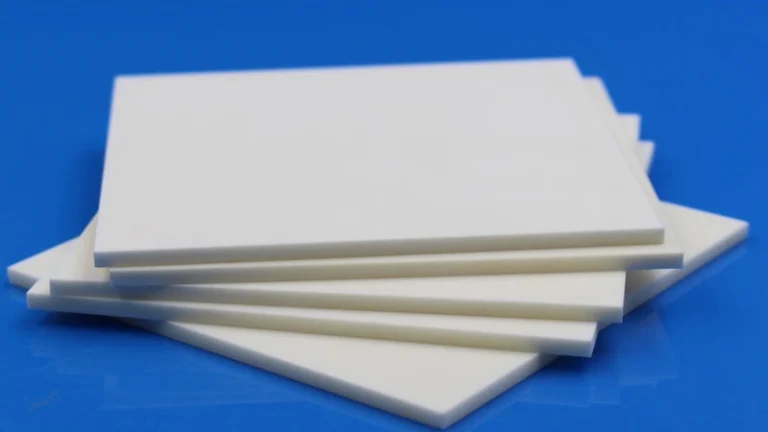

Alumina & Ceramic Components

Used to process dense ceramics like Al₂O₃ and AlN for electronic substrates, insulators, and laser modules. The smooth slicing surface reduces micro-cracking risks.

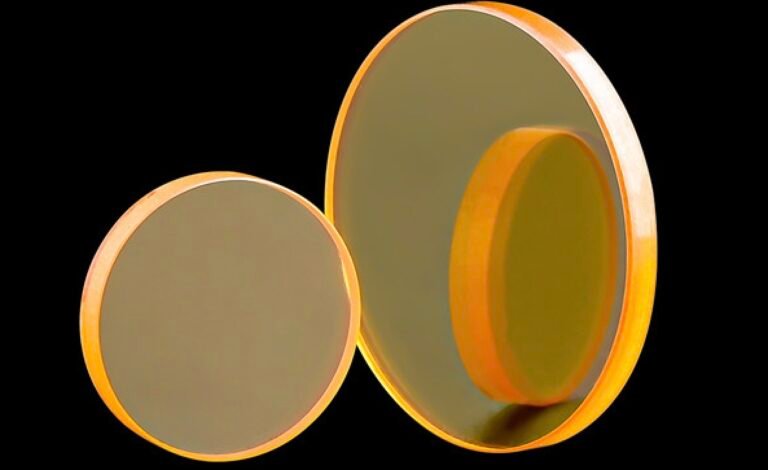

Инфракрасное стекло и кристаллические материалы

Processes specialty glasses like ZnS, Ge, and IR-transmitting ceramics for imaging systems, laser windows, and military optics.

R&D Prototyping of Hard Materials

Университеты и лаборатории полагаются на SGSM 40 для быстрой, точной и воспроизводимой резки небольших партий хрупких и дорогостоящих материалов с минимальными требованиями к оснастке.

ПОЧЕМУ ВЫБИРАЮТ НАС

Высокоскоростная резка бесконечной алмазной проволокой

Высокожёсткая литая конструкция

Высокоточные направляющие и шарико-винтовая передача

Автоматическая система постоянного натяжения

Микронный контроль подачи

User-Friendly Smart Interface

Полностью закрытая защитная конструкция (опционально)

Низкие требования к обслуживанию и высокая экономическая эффективность

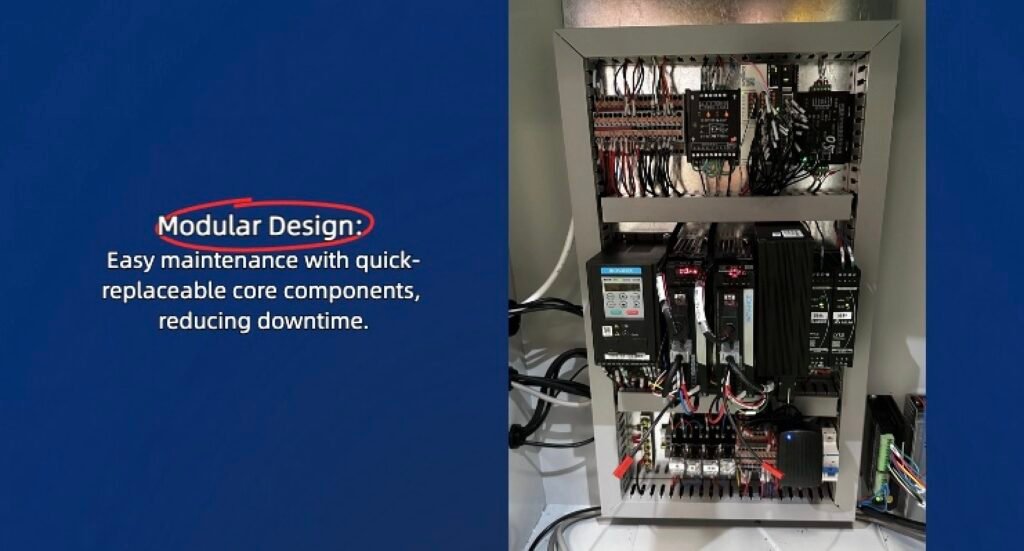

Модульная конструкция

Низкие эксплуатационные расходы и высокая экономическая эффективность

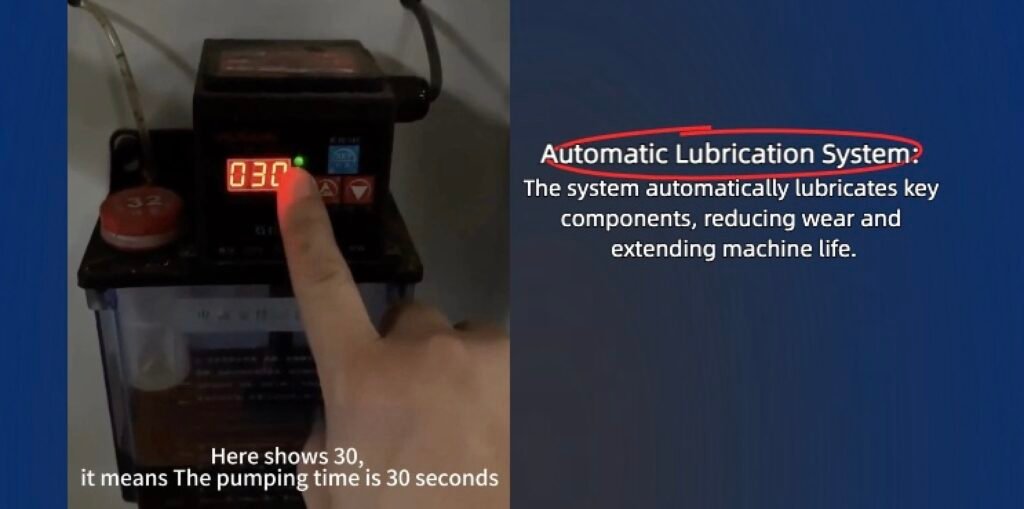

Автоматическая система смазки

Отзывы клиентов

Frequently Asked Questions

Какова максимальная толщина материала, которую может обрабатывать станок при резке?

Оборудование способно выполнять резку пластин толщиной от 0,1 до 350 мм и может работать в автоматическом режиме после настройки программы.

В чём разница между этой проволочной пилой и ленточной пилой (band saw)?

Скорость резки будет примерно одинаковой, но качество поверхности реза у проволочной пилы значительно выше, а потери материала (ширина пропила) — меньше.

Как станок минимизирует потери материала во время резки?

Модель HorizonCrystal оснащена высокоточной алмазной проволокой диаметром от 0,35 до 0,8 мм, благодаря чему ширина пропила остается минимальной.

Каков ожидаемый срок службы алмазной проволоки, и можно ли её заменить самостоятельно?

Срок службы алмазной проволоки зависит от условий эксплуатации и твёрдости обрабатываемого материала. При резке графита одна проволока может обработать примерно 15 квадратных метров. Проволоку можно заменить самостоятельно, и мы предоставляем подробные инструкции по её замене.

Требуется ли для работы станка специальная среда или особые условия установки?

При резке графита на производстве обычно используется пылеуловитель. Его можно подключить к нашему оборудованию во время работы.

Какую техническую поддержку и гарантию вы предоставляете при покупке этого оборудования?

Мы предоставляем комплексную гарантию сроком на 1 год, а также техническую поддержку после покупки — в формате видеоконсультаций или выезда специалиста на место. Это позволяет обеспечить максимально эффективную работу оборудования и оперативное устранение любых возникающих проблем.