Станок для резки призм

SGR 20 — это специализированная алмазная проволочная пила, разработанная для высокоточной резки оптического стекла и керамических призм. Оборудованная программируемым поворотным столом, система может вращать заготовку под заданными углами для многосторонней резки, что делает её идеальной для изготовления призм треугольной, четырёхугольной, пятиугольной и многоугольной формы.

ОСНОВНЫЕ ХАРАКТЕРИСТИКИ

Функция резки призм под различными углами

Вращающийся рабочий стол может поворачиваться на 360°, позволяя пользователю точно задавать углы для призм. Система поддерживает автоматическое формирование треугольников, квадратов, пятиугольников, восьмиугольников и других форм — идеально подходит для заготовки оптических призм.

Автоматическая функция резки

Оператор может запрограммировать различные толщины резки в рамках одной задачи. После установки толщины и количества устройство автоматически выполнит весь цикл резки без необходимости контроля.

Стабильная вертикальная конструкция с защитным корпусом

SGR 40 имеет полностью закрытую вертикальную конструкцию из стали с смотровым окном, обеспечивая безопасность и визуальный контроль во время процесса резки.

Сервоприводы по осям Y и Z с шарико-винтовыми передачами

Оси резки (Y и Z) оснащены сервомоторами, линейными направляющими и ШВП для высокой точности позиционирования — повторяемость до ±0.01 мм и разрешение подачи 0.01 мм.

Сенсорный экран + ручной интерфейс управления

Интуитивно понятная система управления на английском языке позволяет задавать параметры через сенсорный экран. Также предусмотрен ручной контроллер для облегчения выравнивания и вмешательства в работу.

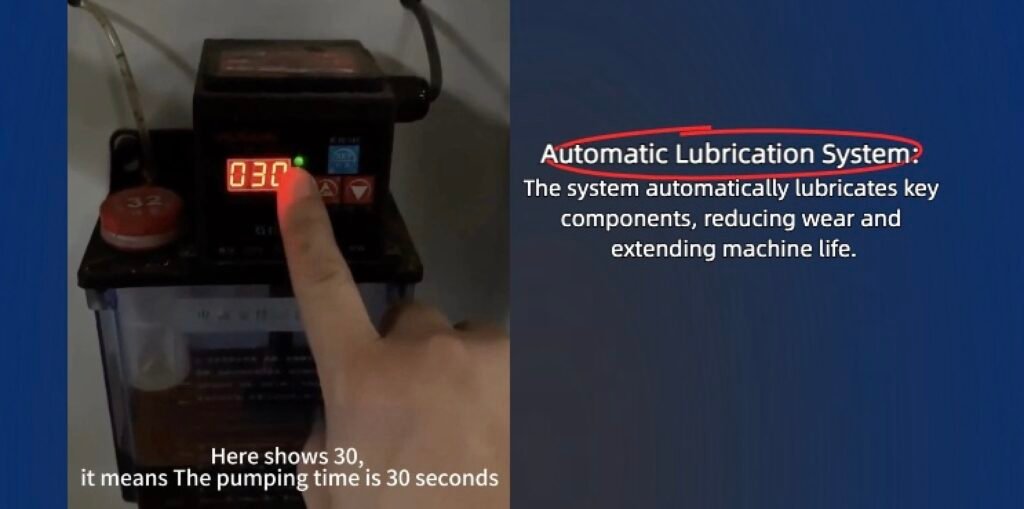

Интегрированная система водяного охлаждения и смазки

Оборудование оснащено системой циркуляции воды и автоматической смазкой для обеспечения чистой и стабильной среды резки.

TECHNICAL SPECIFICATION

| № | Наименование | Технические характеристики |

|---|---|---|

| 1 | Максимальная длина заготовки (мм) | 200 |

| 2 | Максимальная ширина заготовки (мм) | 200 |

| 3 | Максимальная высота заготовки (мм) | 220 |

| 4 | Ход по оси Y (мм) | 200 |

| 5 | Ход по оси Z (мм) | 220 |

| 6 | Максимальная скорость алмазной проволоки (м/с) | 59 |

| 7 | Минимальный шаг подачи по оси Y (мм) | 0.01 |

| 8 | Минимальный шаг подачи по оси Z (мм) | 0.01 |

| 9 | Точность повторного позиционирования по оси Y (мм) | 0.01 |

| 10 | Точность повторного позиционирования по оси Z (мм) | 0.01 |

| 11 | Общая потребляемая мощность (кВт) | 1.5 |

| 12 | Электропитание | 220В 50Гц |

| 13 | Габариты станка (мм) | 1044 × 943 × 1810 |

| 14 | Вес станка (кг) | 560 |

ПРИНЦИП РАБОТЫ ОБЪЯСНЕН

Примеры использования клиентами

МЕТОДЫ РЕЗКИ ПРИЗМ: ОБЗОРНОЕ СРАВНЕНИЕ

Понимание различных методов резки, используемых в производстве призм, помогает лучше представить, где именно применяется SGR 40. Ниже приведён краткий обзор сильных сторон каждого метода и их особенностей:

ОГРАНИЧЕНИЯ И СРАВНЕНИЕ МЕТОДОВ РЕЗКИ ПРИЗМ

Метод резки | Подходит для призм | Преимущества | Ограничения | Типичные материалы |

|---|---|---|---|---|

SGR 40 (ротационная проволочная пила) | ✅ Да | Программируемые углы, чистые кромки, многогранная резка | Не подходит для криволинейной резки | Оптическое стекло, керамические призмы |

Ручная резка + полировка вручную | ⚠️ Ограничено | Низкая стоимость, простая настройка | Плохая повторяемость, высокая трудоёмкость | K9, учебные призмы малого размера |

Профильное шлифование с ЧПУ | ✅ Да | Очень высокая точность, контроль углов | Требует предварительно отрезанных заготовок, дорого | Стекло, оптические кристаллы |

Лазерная резка (высокой мощности) | ⚠️ Условно | Быстро, бесконтактно | Зона термического влияния, риск трещин по краям | Некоторые стекла, мягкая оптика |

Гидроабразивная резка | ✅ Для черновой обработки | Любая форма, подходит для крупных блоков | Грубые края, требуется доработка | Кварц, керамика |

ID-пила (пила с внутренним диаметром) | ❌ Нет | Точная тонкая резка | Не поддерживает углы или многогранную резку | Пластины, керамика |

TARGET CUSTOMERS

Производители оптических компонентов

Компании, производящие призмы, делители луча, клинья и угловые окна для применения в лазерной оптике, системах визуализации, AR/VR и телескопических системах.

Precision Research Labs & Universities

Used for prototyping non-standard optical geometries, slicing experimental glass structures, or preparing multi-facet components in low volumes.

Фабрики по производству кристаллов и лазерной оптики

Идеально подходит для резки многогранных заготовок из кристаллов YAG, BBO или LBO, используемых в лазерных системах высокой мощности, особенно на этапах перед полировкой и нанесением покрытий.

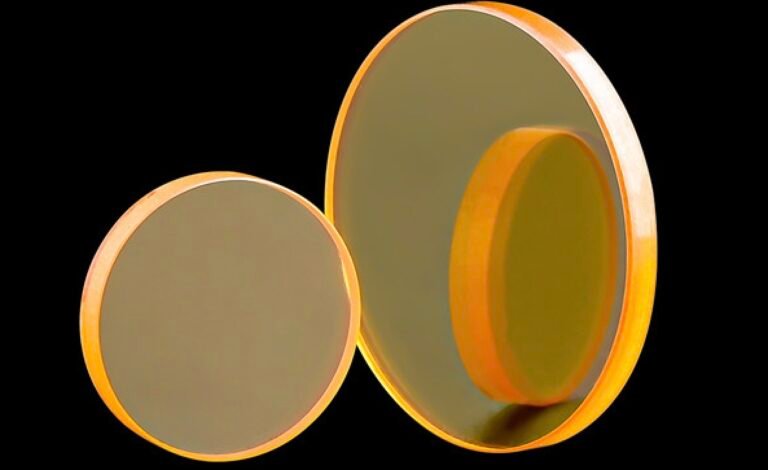

Интеграторы инфракрасной и оборонной фотоники

Идеально подходит для резки инфракрасных материалов на основе ZnS, ZnSe и фторидов под углом для изготовления оптических элементов, используемых в датчиках, системах визуализации и оборонной оптике.

Поставщики стеклянных заготовок и перерабатывающие предприятия

Используются для массового производства многоугольных стеклянных заготовок или предварительно обработанных призм, поставляемых производителям линз или сборщикам оптических систем.

ПОЧЕМУ ВЫБИРАЮТ НАС

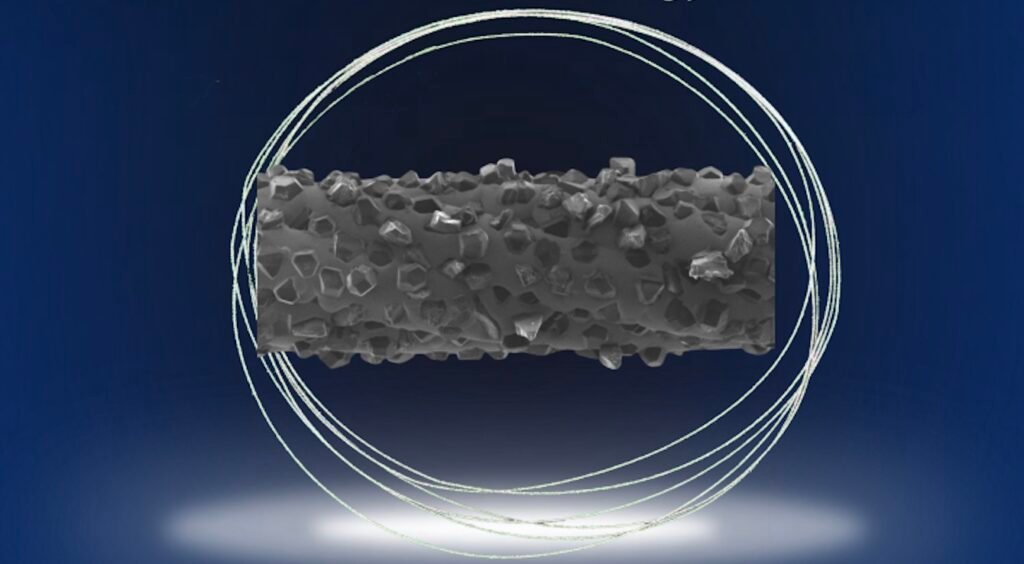

Скоростная резка с помощью бесконечной алмазной проволоки

Высокожёсткая литая конструкция

Высокоточные направляющие и шарико-винтовая передача

Система автоматического постоянного натяжения

Микронный контроль подачи

Удобный интеллектуальный интерфейс пользователя

Полностью закрытая защитная конструкция (опционально)

Низкие требования к обслуживанию и высокая экономическая эффективность

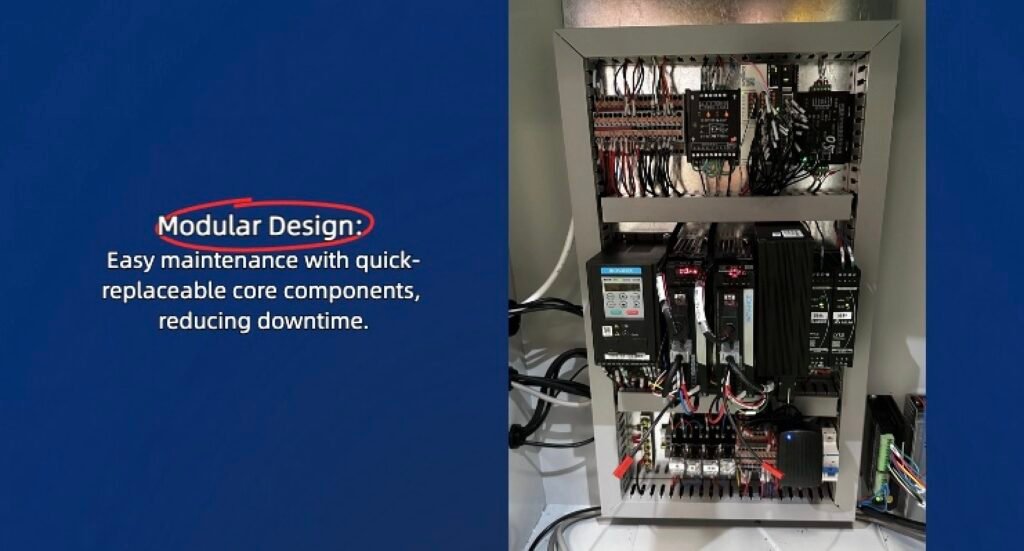

Modular Design

Низкие требования к обслуживанию и высокая экономическая эффективность

Автоматическая система смазки

Отзывы клиентов

Часто задаваемые вопросы

Какова максимальная толщина заготовки, которую может обрабатывать данный станок?

Станок способен выполнять резку заготовок толщиной от 0,1 до 100 мм и может работать в автоматическом режиме после настройки программы.

В чём разница между этой проволочной пилой и ленточной пилой?

Скорость резки будет примерно одинаковой, но качество поверхности среза у проволочной пилы значительно выше, а потери материала (ширина пропила) — меньше.

Как машина минимизирует потери материала во время резки?

HorizonCrystal оснащена высокоточной алмазной проволокой диаметром от 0,35 до 0,8 мм, благодаря чему ширина пропила остается минимальной.

Каков ожидаемый срок службы алмазной проволоки, и можно ли её заменить самостоятельно?

Срок службы алмазной проволоки зависит от условий использования и твердости обрабатываемого материала. При резке графита одна проволока может обработать примерно 15 квадратных метров. Проволока заменяемая пользователем, и мы предоставляем подробные инструкции по её замене.

Требует ли станок специальной среды или условий установки?

При резке графита на объектах заказчиков, как правило, используется система пылеулавливания. Её можно подключить к нашему оборудованию во время работы.

Какой вид технической поддержки и гарантии вы предоставляете при покупке этого оборудования?

Мы предоставляем комплексную гарантию сроком на 1 год, а также техническую поддержку после покупки — в виде видеоинструкций или выездного обслуживания. Это обеспечивает максимальную эффективность работы оборудования и оперативное решение любых возникающих проблем.