Станок для резки стеклянных пластин

SG 20 — это высокоточный проволочный резак с портальной конструкцией, специально разработанный для резки мелких деталей из оптического стекла, кристаллов и керамики. Благодаря полностью закрытому корпусу, сенсорному интерфейсу и автоматическому контролю толщины, он обеспечивает исключительную производительность как для НИОКР, так и для мелкосерийного производства.

КЛЮЧЕВЫЕ ОСОБЕННОСТИ

Высокоточная резка для малогабаритных заготовок

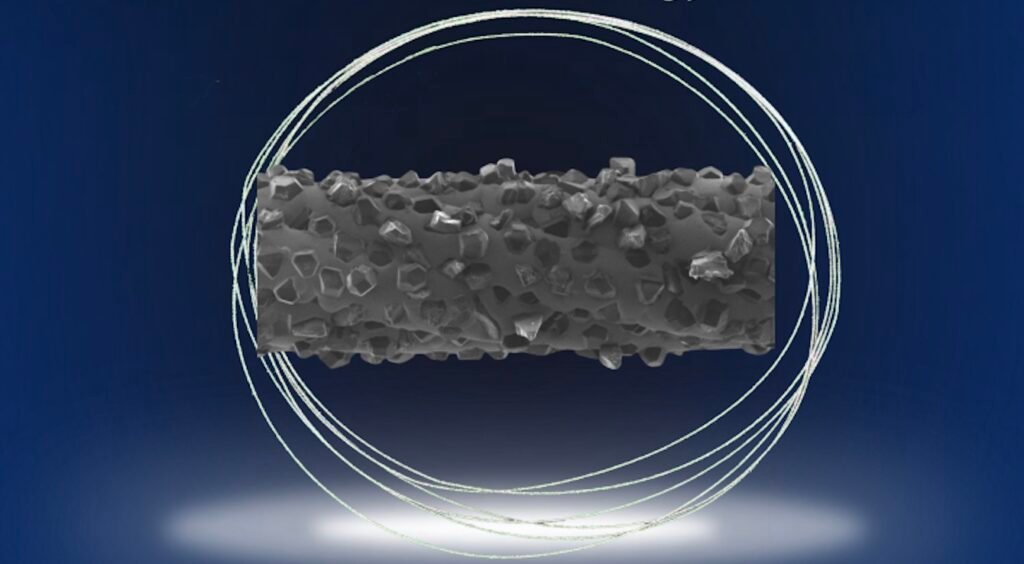

Оборудование способно резать детали размером до 200 × 200 × 220 мм, используя бесконечную алмазную проволоку диаметром Ø0.3–1.0 мм для чистой и малотравмирующей резки твердых, хрупких или ценных материалов.

Два режима резки: равномерная и переменная толщина

Оператор может выбирать между режимом постоянной толщины или настраиваемой резкой до 10 различных слоев в одной программе.

Полностью закрытая портальная конструкция

Компактная, но прочная рама портального типа с защитными дверцами обеспечивает безопасную и тихую работу, снижает загрязнение и разбрызгивание.

Интеллектуальная система управления резкой

Интерфейс управления на базе сенсорного экрана и кнопок поддерживает:

Компенсацию пропила

Режимы с отслаиванием и без

Настройку толщины среза в реальном времени

Обнаружение обрыва проволоки и сигнализацию

Отслеживание производства и автоматическое отключение

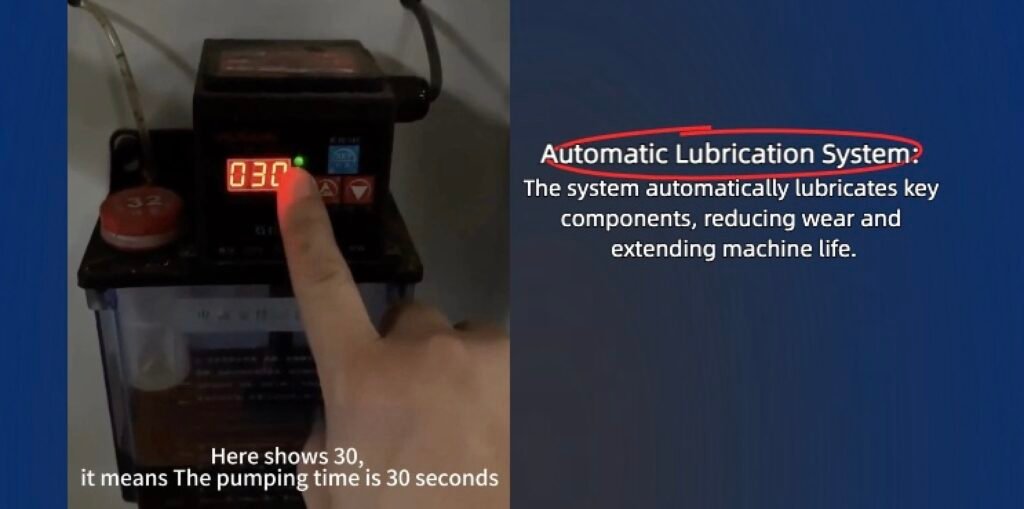

Автоматическая смазка и жидкостное охлаждение

Оборудовано системой циркуляции воды и автоматической смазкой, обеспечивающими чистые условия резки и сниженный износ компонентов.

Поддержка системы сбора масляного тумана

Совместимо с дополнительными установками сбора масляного тумана для более чистой лабораторной или производственной среды.

Технические характеристики

№ | Наименование | Технические характеристики |

|---|---|---|

1 | Максимальная длина заготовки (мм) | 200 |

2 | Максимальная ширина заготовки (мм) | 200 |

3 | Максимальная высота заготовки (мм) | 220 |

4 | Ход по оси Y (мм) | 200 |

5 | Ход по оси Z (мм) | 220 |

6 | Максимальная скорость алмазной проволоки (м/с) | 58 |

7 | Минимальный шаг подачи по оси Y (мм) | 0.01 |

8 | Минимальный шаг подачи по оси Z (мм) | 0.01 |

9 | Точность повторного позиционирования по оси Y (мм) | 0.01 |

10 | Точность повторного позиционирования по оси Z (мм) | 0.01 |

11 | Общая потребляемая мощность (кВт) | 1.5 |

12 | Электропитание | 220В 50Гц |

13 | Габариты станка (мм) | 1044 × 943 × 1810 |

14 | Вес станка (кг) | 400 |

КАК SG 20 ВЫПОЛНЯЕТ ПОЛНЫЙ ЦИКЛ РЕЗКИ

SG 20 НА ОБЪЕКТАХ КЛИЕНТОВ

Сравнение методов резки

Вот таблица сравнения методов резки: SG 20 против ID-пилы и ленточной пилы (Band Saw), с акцентом на точность, качество поверхности и удобство эксплуатации:

Характеристика / Метод | SG 20 (алмазная проволочная пила) | ID-пила (пила с внутренним диаметром) | Ленточная пила |

|---|---|---|---|

Точность резки | ⭐⭐⭐⭐ ≤ 0.05 мм | ⭐⭐⭐⭐ Высокая | ⭐ Низкая |

Качество поверхности | ⭐⭐⭐⭐ Гладкая, без сколов | ⭐⭐⭐ Хорошее (требуется полировка) | ⭐ Грубая, сколы |

Контроль толщины среза | ⭐⭐⭐⭐ Программируемый + мульти-режим | ⭐⭐ Ручная настройка под каждый рез | ❌ Нет |

Ширина пропила (kerf) | ⭐⭐ 0.3–0.6 мм | ⭐ 0.15–0.3 мм | ❌ >1.0 мм |

Простота эксплуатации | ⭐⭐⭐⭐ Сенсорный экран + автоподача | ⭐⭐ Требуется обучение | ⭐ Очень базовая |

Ресурс инструмента и стоимость | ⭐⭐ Средний | ❌ Высокая изнашиваемость и замена дорогая | ⭐⭐ Низкая |

Совместимость с материалами | ⭐⭐⭐⭐ Стекло, керамика, кристаллы | ⭐⭐ Тонкие пластины, ограниченные размеры | ⚠️ Только крупные блоки |

Поддержка автоматизации | ✅ Полностью автоматический рез | ❌ Шаг за шагом вручную | ❌ Нет |

📌 Вывод: SG 20 обеспечивает идеальный баланс между точностью, качеством и удобством, особенно для хрупких и ценных материалов в лабораторных и производственных условиях.

Типичные области применения

Резка оптического стекла

Используется для резки фильтрующего стекла, окон с выборочной пропускной способностью, заготовок для лазерной оптики и защитных стеклянных подложек в малых партиях или в исследовательских целях.

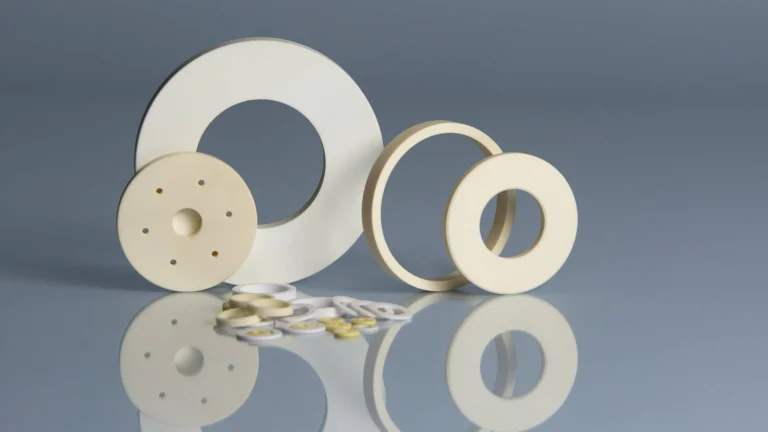

Подготовка керамических материалов

Идеально подходит для резки окиси алюминия, нитрида алюминия или спечённой керамики для нужд электронной упаковки, термоизоляции или радиочастотных компонентов.

Резка кристаллов

Обеспечивает точную резку кварцевых пластин, заготовок YAG или других фотонных кристаллов для последующей полировки или раскроя.

Подготовка исследовательских образцов

Популярна в академических лабораториях для создания тестовых образцов из твёрдых или хрупких материалов с контролируемой толщиной — поддерживает режимы многослойной резки, компенсации ширины пропила и съёмной резки.

ПОЧЕМУ ВЫБИРАЮТ НАС

Скоростная резка с помощью бесконечной алмазной проволоки

Высокожесткая литая конструкция

Высокоточные направляющие и шарико-винтовая передача

Автоматическая система постоянного натяжения

Микронный контроль подачи

Удобный интеллектуальный интерфейс пользователя

Полностью закрытая защитная конструкция (опционально)

Low Maintenance & Cost Efficiency

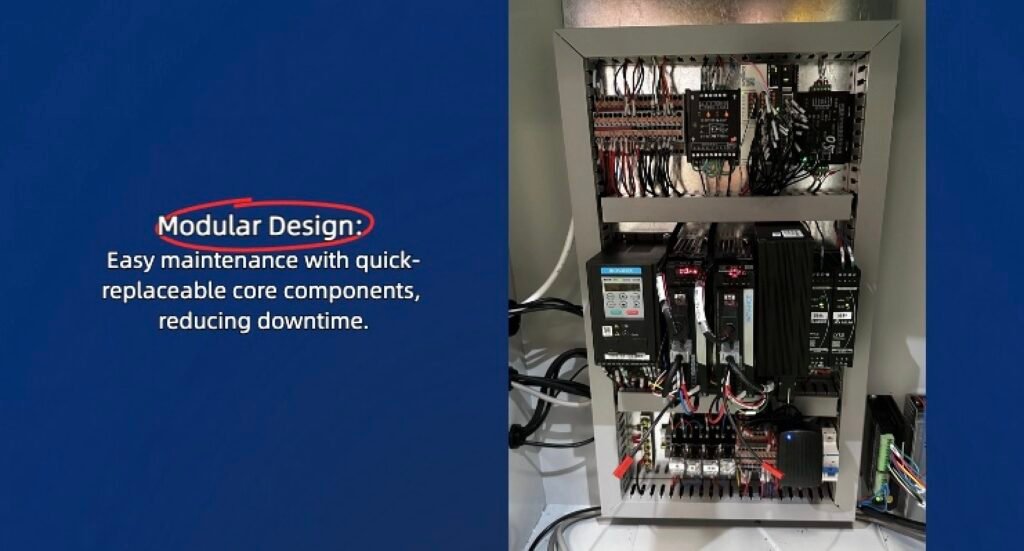

Modular Design

Низкие затраты на обслуживание и высокая экономическая эффективность

Автоматическая система смазки

Отзывы клиентов

Optical Division

Часто задаваемые вопросы

Какова максимальная толщина заготовки, которую может обрабатывать станок при резке?

Станок способен выполнять резку с толщиной от 0,1 до 200 мм и может работать в автоматическом режиме после настройки программы.

В чём разница между этой проволочной пилой и ленточной пилой?

Скорость резки будет примерно одинаковой, но качество поверхности реза у проволочной пилы значительно выше, а потери материала (ширина пропила) — меньше.

Как станок минимизирует потери материала во время резки?

Модель HorizonCrystal оснащена высокоточной алмазной проволокой диаметром от 0,35 до 0,8 мм, что обеспечивает очень узкий пропил.

Каков ожидаемый срок службы алмазной проволоки, и можно ли её заменить самостоятельно?

Срок службы алмазной проволоки зависит от условий эксплуатации и твёрдости материала. При резке графита одна проволока может обработать примерно 15 квадратных метров. Проволоку можно заменить самостоятельно, и мы предоставляем подробные инструкции по её замене.

Требует ли станок специальной среды или условий установки?

При резке графита на предприятии, как правило, используется пылеуловитель. Его можно подключить к нашему станку во время работы.

Какую техническую поддержку и гарантию вы предоставляете при покупке этого оборудования?

Мы предоставляем полную гарантию сроком на 1 год, а также видеоподдержку или техническую поддержку на месте после покупки, чтобы обеспечить эффективную работу вашего оборудования и оперативное решение любых возникающих вопросов.