Добавьте здесь заголовок

Полностью покрытая алмазная кольцевая проволока — это гальваническая бесконечная проволока, предназначенная для высокоточной резки хрупких, твёрдых и ценных материалов. Алмазный абразив равномерно распределён по всей окружности проволоки, что обеспечивает стабильное давление при резке и высокое качество поверхности на протяжении всего срока службы петли.

Этот тип проволоки идеально подходит для пользователей, которым требуется чистый рез с минимальными сколами, узкий пропил и высокая износостойкость. Широко применяется в оптике, керамике, полупроводниковой промышленности и передовых материалах.

ОСНОВНЫЕ ХАРАКТЕРИСТИКИ

Абразивное покрытие по всей окружности

Алмазное зерно равномерно нанесено методом гальванического осаждения по всей внешней поверхности кольцевой проволоки, что обеспечивает равномерное снятие материала и минимальную вибрацию во время резки.

Стабильные и воспроизводимые результаты

Обеспечивает одинаковое качество реза при каждом использовании, что особенно важно для производственных задач и научных исследований с жёсткими допусками.

Финишная поверхность как после шлифовки

Минимизирует микротрещины и повреждение кромок, создавая чистую поверхность, пригодную для последующей полировки или прямого использования.

Узкая ширина пропила

Типичная ширина пропила составляет от 0,3 до 0,6 мм, что позволяет сократить потери материала и получить больше срезов с одного блока.

Индивидуальные размеры кольца

Каждая проволочная петля изготавливается под конкретные размеры вашего оборудования — от 1000 мм до более 5000 мм по окружности.

Совместимость с различными материалами

Эффективно работает со следующими хрупкими материалами: оптическое стекло, кварц, плавленый кремнезём, оксид алюминия, сапфир, нитрид галлия (GaN) и полупроводники.

Технические характеристики

Диаметр проволоки | Тип покрытия | Рабочее натяжение (Н) | Разрывное натяжение (Н) | Рекомендуемая длина | Примеры применений |

|---|---|---|---|---|---|

0,30 мм | Полное | 60 | 115 | 1M – 30M | Сапфир, кварц, фильтры |

0,35 мм | Полное | 75 | 150 | 1M – 30M | Оптическое стекло, керамические мишени |

0,50 мм | Полное | 100 | 200 | 1M – 30M | Техническая керамика, магниты |

0,60 мм | Полное | 115 | 270 | 1M – 30M | Сапфировые блоки, кристаллы |

0,80 мм | Полное | 210 | 440 | 1M – 30M | Плавленый кварц, крупные оптические элементы |

1,00 мм | Полное | 250 | 500 | 1M – 30M | Стеклокомпозиты, керамика |

3 типа гальванической алмазной кольцевой проволоки

Полностью покрытая гальваническая алмазная кольцевая проволока

Режущая проволока с полным покрытием сравнительно тонкая — минимальный диаметр составляет 0,3 мм.

Такая проволока особенно эффективна при резке твёрдых и хрупких материалов, таких как кварц, кремниевые стержни, оптическое стекло и редкоземельные металлы.

Полное покрытие проволоки обеспечивает наличие большого количества алмазных зерен по всей её поверхности, что придаёт ей высокую режущую способность.

Поэтому она особенно хорошо подходит для резки материалов с небольшим объёмом снятия стружки и высокой твёрдостью.

Наша полностью покрытая проволока отличается не только высокой плотностью абразива, но и использованием смеси природных и дроблёных алмазов, что делает её одновременно острой и износостойкой.

Благодаря этому срок службы такой проволоки значительно дольше, чем у аналогов.

Сегментированная гальваническая алмазная кольцевая проволока

Минимальный диаметр сегментированной проволоки составляет 0,8 мм.

Сегментное покрытие создаёт свободные промежутки на поверхности проволоки, что позволяет накапливать большое количество стружки в процессе резки.

При вращении проволоки срезанный материал эффективно удаляется, что значительно повышает способность к удалению отходов.

Этот тип проволоки особенно хорошо справляется с резкой таких материалов, как графит и гофрированная бумага, которые не обладают высокой твёрдостью, но образуют много пыли.

Резьбовая (спиральная) гальваническая алмазная кольцевая проволока

Минимальный диаметр резьбовой проволоки — 0,5 мм.

Резьбовое покрытие формирует спиральные зазоры на поверхности проволоки, создавая вместимость для сбора большого объёма стружки.

В процессе вращения проволока уносит и удаляет отходы, значительно увеличивая производительность при удалении материала.

Эти проволоки также отлично подходят для резки пыльных, но не очень твёрдых материалов, таких как графит и гофрированная бумага.

Дополнительная информация

Полностью покрытые гальванические алмазные проволоки широко применяются в резке материалов, где возможно использование охлаждающей жидкости.

В то время как сегментированные и резьбовые проволоки в основном используются для сухой резки.

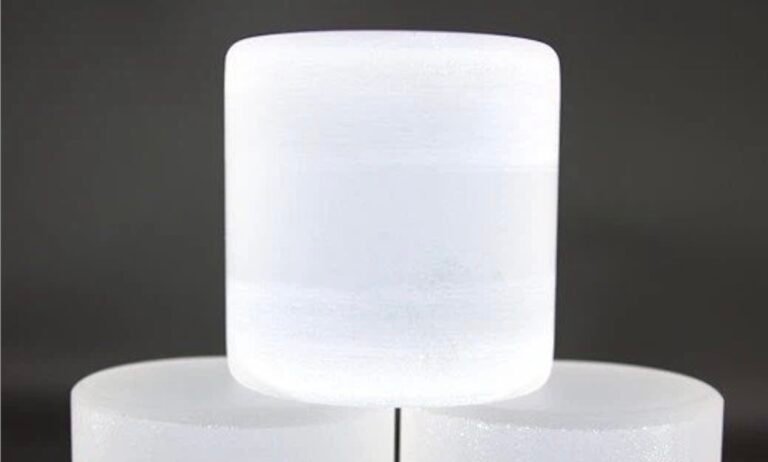

КАК ВЫГЛЯДИТ ГАЛЬВАНИЧЕСКАЯ АЛМАЗНАЯ КОЛЬЦЕВАЯ ПРОВОЛОКА

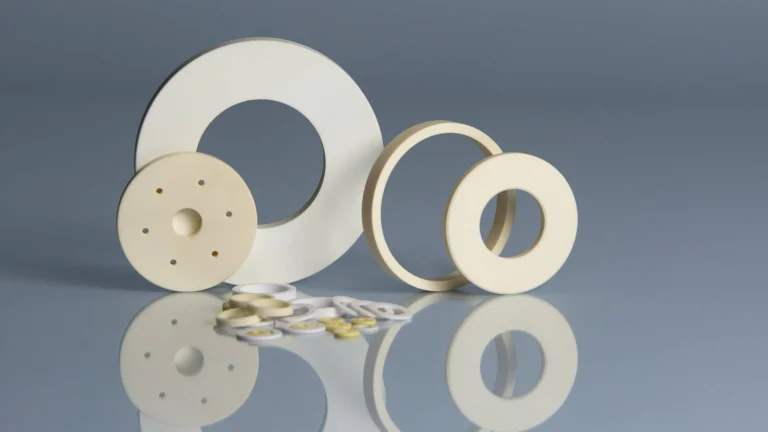

МАТЕРИАЛЫ, КОТОРЫЕ РЕЖЕТ ГАЛЬВАНИЧЕСКАЯ АЛМАЗНАЯ КОЛЬЦЕВАЯ ПРОВОЛОКА

Резка оптического стекла

Фильтры, купола, заготовки призм

Сапфир

Резка слитков и пластин (ваферов)

Плавленый кварц и кремнезём

Производство компонентов

Магнитная керамика

Резка материалов

Кремний

Обработка пластин из составных полупроводников

Отзывы клиентов

Часто задаваемые вопросы

Какие материалы можно резать с помощью бесконечной алмазной проволочной пилы?

Как пользоваться пилой с бесконечной алмазной проволокой?

You need a wire saw machine which can tention the cutting wire.buy one or manully make one.

Каков срок службы пилы с бесконечной алмазной проволокой?

Какова длина проволоки?

Если проволока порвётся, можно ли её соединить и использовать снова?

Как я могу приобрести алмазную кольцевую проволоку?

Let us konow your required wire dia and wire length, we will send the diamond wire loop to your location by DHL or Fedex.